Introduction to Litho Printing

Litho printing, short for lithography printing, is a widely used printing technique known for its high quality and precision. It involves the use of a flat metal or stone surface to create an image or text. This method is particularly popular for large-scale commercial printing due to its ability to produce consistent, sharp images.

History of Lithography

Lithography was invented in the late 18th century by Alois Senefelder, a German playwright.

Originally, lithography utilized limestone as the printing surface. Senefelder discovered that grease-based materials, like wax or oil, could be used to create an image on the smooth surface of the stone. When the stone was moistened and inked, the greasy image would attract the ink, while the wet non-image areas would repel it.

It revolutionized the printing industry by introducing a new way to reproduce images on paper. Originally, it used limestone as the printing surface, but modern litho printing now utilizes metal plates for enhanced durability and efficiency.

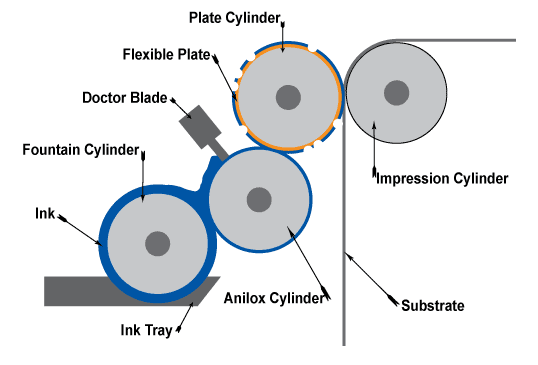

The Litho Printing Process

1. Plate Preparation

The initial phase is plate preparation, a critical step that sets the foundation for the entire process.

The printing plate, often composed of aluminum, is meticulously coated with a photosensitive emulsion. This emulsion is engineered to be responsive to UV light. A meticulously crafted film negative, accurately representing the desired image, is then aligned and exposed to UV light.

This exposure instigates a chemical reaction, causing the emulsion in illuminated areas to harden while unexposed regions retain solubility.

2. Ink Application

With the plate now prepared, the next stage is ink application. Specialized lithographic inks, formulated to adhere precisely to the treated surface, are skillfully applied. The ink uniformly covers the plate, adhering exclusively to the hardened, image-bearing areas.

This step is pivotal in determining the vibrancy and quality of the final print.

3. Printing

The printing phase is where the plate and the printing surface converge. Typically, this surface is premium paper, chosen for its receptivity to the ink and final print quality. The plate is meticulously aligned with the paper, ensuring precise registration.

A lithographic press applies controlled pressure, compelling the inked plate to make contact with the paper. This pressure effectuates the transfer of ink, rendering a faithful reproduction of the original image.

Advantages of Litho Printing

1. High-Quality Reproduction

Litho printing excels at reproducing intricate details, fine lines, and subtle tonal variations with exceptional precision. This results in sharp, vibrant images and text, making it ideal for projects that demand a high level of visual fidelity.

2. Consistency Across Large Print Runs

One of the hallmark advantages of litho printing is its ability to maintain consistent print quality over extensive print runs. This ensures that the first print mirrors the last in terms of color accuracy and detail, which is critical for projects requiring large quantities of identical prints.

3. Versatility in Substrate Choice

Litho printing is compatible with a wide range of materials, including paper, cardboard, plastics, and even some metals. This versatility allows for a diverse array of applications, from packaging materials to marketing collateral, providing adaptability to various industries.

4. Cost-Effectiveness for Large Quantities

Once the initial setup is complete, litho printing becomes highly cost-effective for large print runs. The efficiency of reproducing a high volume of prints makes it a cost-efficient choice for projects with extensive print requirements.

5. Accurate Color Matching

The process of litho printing allows for precise color matching, ensuring that the printed materials align seamlessly with the intended design. This level of accuracy is particularly crucial for branding materials and marketing collateral.

6. Ability to Handle Complex Designs

Litho printing can effectively reproduce intricate and detailed graphics, making it suitable for projects with complex designs, such as fine art reproduction or intricate packaging.

7. Prints with Minimal Burstiness and Perplexity

Due to the controlled nature of the process, litho printing exhibits minimal burstiness (variance in ink distribution) and perplexity (variation in print density). This results in highly defined, clear prints with consistent quality.

8. Professional Presentation

The precise and high-quality output of litho printing imparts a professional and polished appearance to printed materials. This is particularly advantageous for marketing materials, packaging, and commercial prints where a professional image is imperative.

Applications of Litho Printing

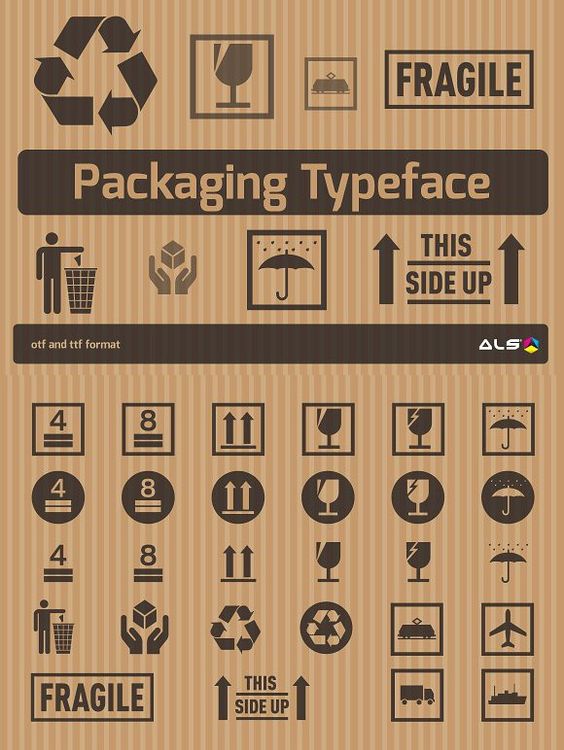

1. Packaging and Labeling

In the realm of packaging, litho printing reigns supreme. It is the go-to choice for creating detailed, visually striking labels and packaging materials. From product labels to intricate packaging designs for cosmetics, food, pharmaceuticals, and other consumer goods, Litho Printing excels at rendering sharp, vibrant graphics on packaging substrates.

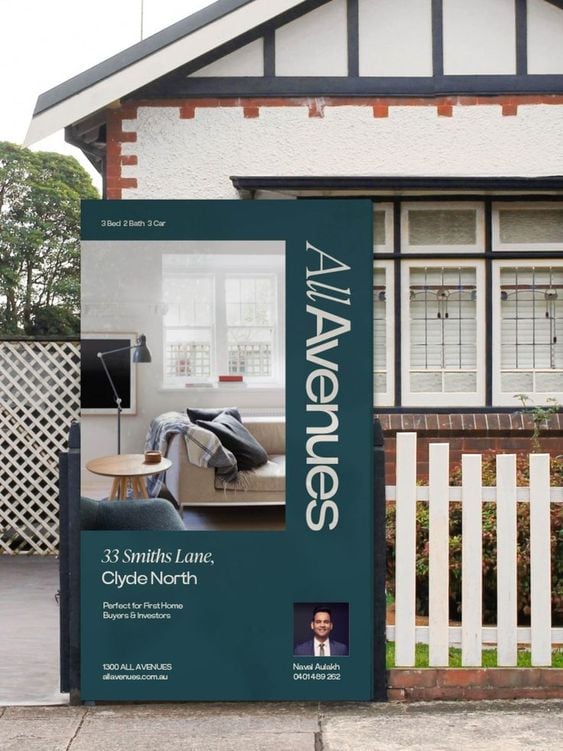

2. Marketing Collaterals

Lithography is widely utilized in the production of marketing materials. Brochures, pamphlets, flyers, and posters all benefit from the precision and high-quality reproduction capabilities of Litho Printing. It ensures that marketing collateral presents a professional image, effectively communicating the intended message.

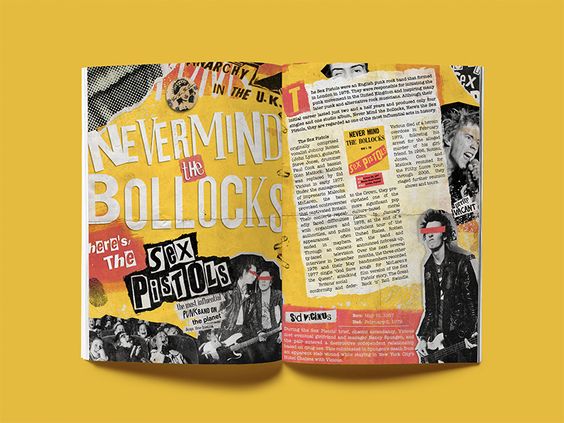

3. Newspapers and Magazines

Traditional print media, such as newspapers and magazines, have long relied on litho printing for its ability to consistently produce high-resolution images and text. The process allows for the mass production of periodicals without compromising on print quality, ensuring clear and legible content for readers.

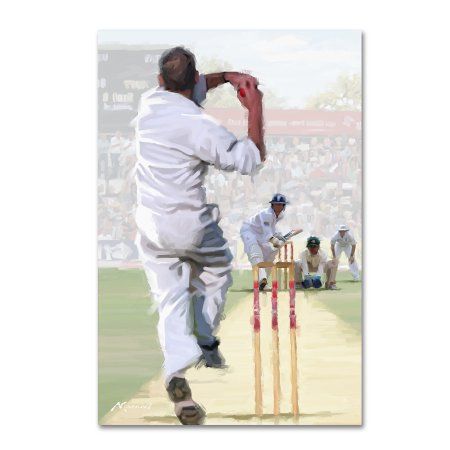

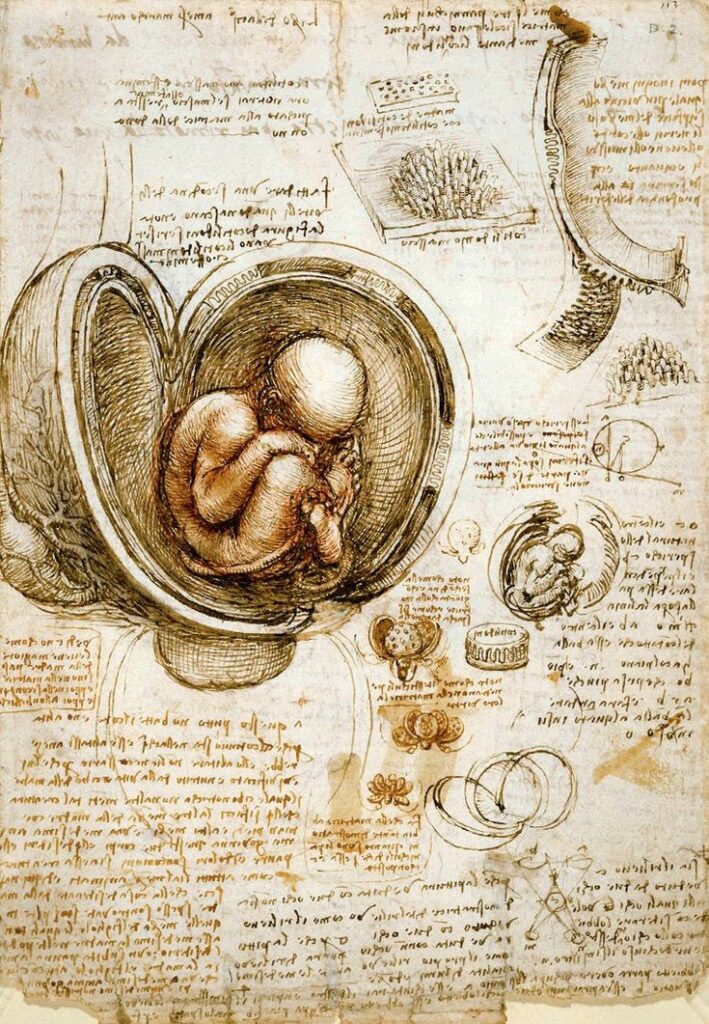

4. Fine Art Reproduction

Artists and museums often turn to litho printing for the reproduction of fine art pieces. Its capacity to faithfully replicate intricate details and color nuances makes it an invaluable tool in art preservation and dissemination. Lithography allows for the creation of high-quality art prints that closely mirror the original work.

5. Commercial Printing

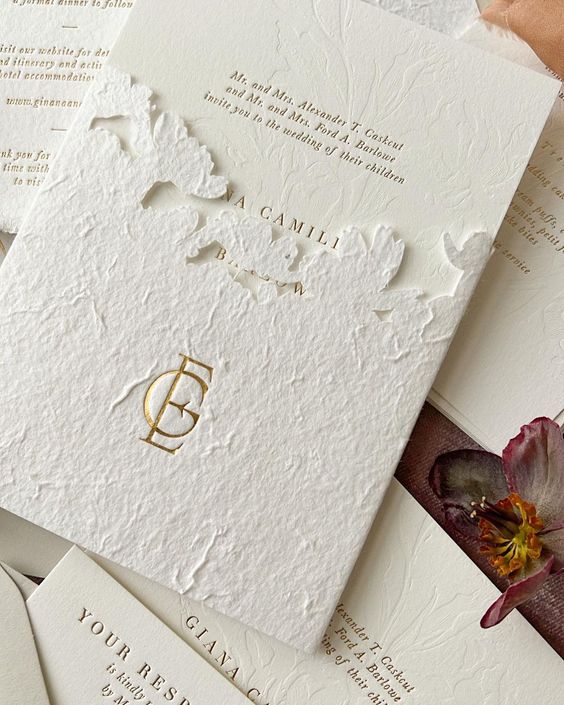

From business stationery to event invitations, litho printing is a staple in commercial printing. Its ability to produce crisp, detailed text and images makes it an ideal choice for materials requiring a polished and professional appearance.

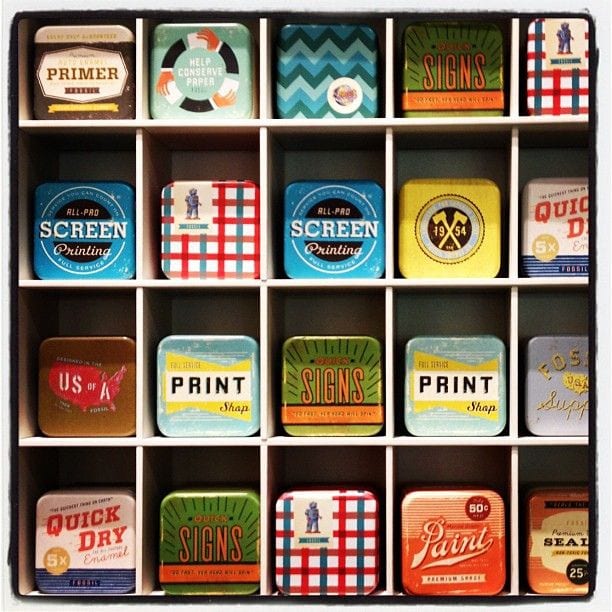

6. Specialized Printing

Litho printing also lends itself to specialized applications, such as printing on specific substrates like plastics, metallic foils, and tinplate. If you are making customized tin boxes in large quantities, manufacturers use lithographic printing methods to print the designs.

The process is particularly adept at rendering precise and vibrant graphics on tinplate surfaces, making it a crucial technique for industries that utilize tin cans and containers.

Comparing Litho Printing with Other Printing Methods

While litho printing excels in certain areas, it’s essential to consider other printing methods like digital and flexography for specific projects. Each method has its strengths and weaknesses, and choosing the right one depends on factors such as quantity, budget, and desired quality.

| Printing Method | Key Advantages | Suitable Applications |

|---|---|---|

| Offset Lithography | – Precise color matching – High-quality reproduction – Cost-effective for large runs | – Packaging and labeling – Marketing materials – Newspapers and magazines – Fine art reproduction |

| Digital Printing | – Suitable for short print runs – Quick turnaround times – Variable data printing capability | – Marketing materials – Short-run projects – On-demand printing |

| Flexography | – Printing on flexible substrates – Fast printing speeds – Cost-effective for large quantities | – Packaging and label printing – Newspapers – Flexible packaging |

| Gravure Printing | – Deep, rich colors – High-quality images – Ideal for high-volume, long-run printing | – Magazines – Packaging – Decorative materials |

| Screen Printing | – Versatility in substrate choice – Can print on irregular surfaces – Suitable for various materials | – Custom apparel – Signage – Promotional items |

| Letterpress Printing | – Tactile quality with deep impressions – Ideal for specialty printing – Unique aesthetic appeal | – High-end stationery – Specialty printing projects – Invitations |

| Intaglio Printing | – Fine detail and precise line work – Exceptional quality for detailed images – Intaglio engraving process | – Banknotes – Fine art prints – Engraved invitations |

| Thermography | – Raised, tactile text and graphics – Cost-effective alternative to engraving | – Invitations – Business cards – Stationery |

| Embossing and Debossing | – Adds texture and depth to prints – Creates a tactile experience – Enhances visual appeal | – Invitations – Packaging – Business cards |

Environmental Impact of Litho Printing

In recent years, the printing industry has made strides towards more sustainable practices. Litho printing, while efficient, does involve the use of chemicals. However, efforts are being made to develop eco-friendly alternatives and implement recycling programs.

Future Trends in Litho Printing

With advancements in technology, litho printing is poised to become even more efficient and environmentally friendly. Digital integration and automation are expected to play a significant role in the future of this printing method.

Tips for Successful Litho Printing

- Plate Preparation Precision: Ensure meticulous preparation of the printing plate for accurate image reproduction.

- Ink Quality Matters: Use high-quality lithographic ink to ensure vibrant and consistent prints.

- Maintain Optimal Ink Levels: Monitor and adjust ink levels for uniform coverage and color accuracy.

- Paper Selection Is Key: Choose suitable paper stock based on weight, finish, and absorbency for optimal results.

- Calibration is Crucial: Regularly calibrate equipment to maintain accurate color reproduction and registration.

- Monitor and Control Humidity: Maintain consistent humidity levels in the printing environment to prevent paper expansion or contraction.

- Regular Equipment Maintenance: Keep rollers, plates, and press components clean and well-maintained for smooth operation.

- Proper Storage of Plates: Store plates in a controlled environment to prevent damage or deterioration.

- Monitor Ink and Water Balance: Maintain the right balance between ink and water to prevent issues like emulsification.

- Handle Plates with Care: Avoid damage during handling to ensure accurate image transfer.

- Perform Test Runs: Conduct test prints to verify color accuracy and registration before large print runs.

- Inspect Prints During Run: Continuously monitor prints for any issues and make necessary adjustments.

- Maintain a Clean Working Environment: A clean workspace helps prevent contamination and ensures quality prints.

- Quality Control Checks: Conduct regular quality checks during production to catch any issues early on.

- Document Settings and Adjustments: Keep a record of successful print settings for reference in future projects.

Maintenance and Care of Litho Printing Equipment

Regular maintenance is crucial to prolonging the lifespan of litho printing equipment. This includes cleaning rollers, inspecting plates for wear, and lubricating moving parts.

Conclusion

Litho printing remains a cornerstone of the printing industry, known for its precision and high-quality output. As technology advances, we can expect even more efficient and sustainable practices in this field.

FAQs

Q: Is litho printing suitable for small print runs?

A: Yes, while it’s known for large-scale printing, litho can produce excellent results for smaller quantities as well.

Q: How long does it take to set up a litho printing job?

A: Set-up time depends on factors like plate preparation and the complexity of the project, but it’s generally efficient for large runs.

Q: Can litho printing be used for specialized inks or finishes?

A: Yes, litho printing allows for the use of various inks and finishes to achieve specific effects.

Q: Is litho printing environmentally friendly?

A: Efforts are being made to improve the environmental impact of litho printing, but it does involve the use of chemicals.

Q: What industries benefit most from litho printing?

A: Litho printing is widely used in industries like packaging, marketing, publishing, and fine art reproduction.