Cookie Tins Empty

Finetins is an excellent factory of cookie tins in China. As we extend our expertise in selling cookie tins, we can assist you with customization. Get in touch with us to discuss your needs. We can have the shape, capacity, and design according to your requirements.

We provide tin packaging solutions for many of the world’s leading cookie brands. Here are some of our popular cookie tins.

Cookie Tins Empty

Cheap Cookie Tins

Cookie Gift Tins

Personalized Cookie Tins

Big Cookies Tin Packaging

Cookie Tins With Company Logo

Cookie Tins With Window Top

Skullcandy Cookie Tin Packaging

Cookie Storage Tins

Decorative Cookie Tins

Square Cookie Tins

Round Cookie Box Set

Metal Cookie Tin

Printed Cookie Tins

Double Layer Cookies Tin

Large Cookie Tins With Lids

Danish Cookie Tin

Round Cookie Tins

Cookies in a Red Tin

Large Cookie Tins

Small Cookie Tins

Tin Can Cookies

Custom Tin Packaging For Cookies

Blue Tin Cookies

Tin Cookie Box

Still not finding what you’re looking for?

Contact our consultants for more available cookie tins.

Custom your cookie tins with different print, multi-colors, different material, shapes, and features. High quality printing, offer free sample delivery!

MOQ From 5000 PCS.

Finetins has been producing hundreds of million cookie tins for clients around the world. We can produce 50,000 cookie tins per day. Usually, we can finish the first order in 20 days and repeat orders in 15 days.

Good or bad packaging directly affects the sales of your cookies. If you don’t know much about cookie tins, please check out our guide.

We can produce more than that!

Please note that Finetins are a tin packaging manufacturer. We has produced thousands of types of tin packaging. We can produce any process of tin products.

Finetins provides customers with one-stop service of cookie tins. 99% of the customers in cooperation with Finetins are satisfied with our service.

With our supporting team of professional designers, we can turn your cookie tins information into product rendering.

We offer pro-active optimization of cost, design, manufacturing and logistics to ensure you save time and money. We can answer all your questions about cookie tins.

With our QC team, we’re committed to continually improving the quality of our cookie tins and services for the best customer experience.

As for the continuous research on the production process, we provide the customers with top quality cookie tin packaging. Make the consumers purchase your products without hesitation due to the perfect packaging.

After confirming the intention of cooperation, we will make free samples according to your needs. We can modify the sample for many times with the consideration of your complete satisfaction.

If you don’t have a freight forwarder, our freight team and shipping partners find end-to-end distribution solutions to deliver your cookie packaging on the fly, or through scheduled periodic delivery programs.

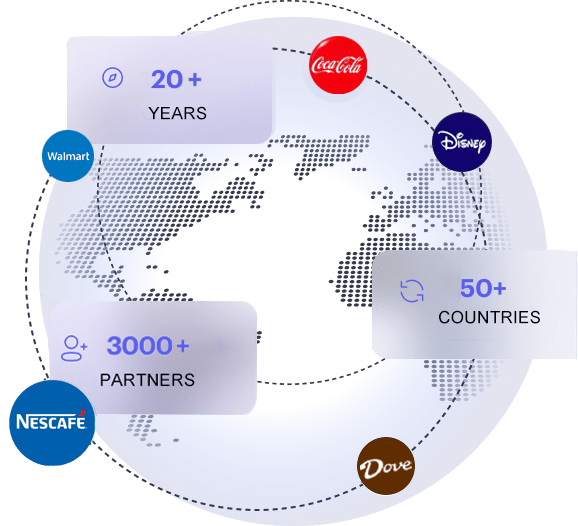

As for the cooperation with customers, we have more than 3,000 successful cases in all. Every successful case is closely connected with our enthusiastic and professional service, in addition to the trust from our customers. With this library, you can establish your ideal structure that is tailored to your cookie business.

The following cooperation cases are released officially with the consent of the customers.

If you are a brand owner or manufacturer of cookies, you must know the best-selling products very well. Whether the cookies are tasty or not is the first priority, followed by the packaging. Good cookie tins can significantly increase the sales of your product.

Cookie tins are metal outer packaging, often used for high-end gifts, food, or card outer packaging. Cookie tins are mainly used for packaging cookies, biscuits and other puffed food. A typical cookie tin is cylindrical in shape and has a lid that can be opened and closed. Cookie tins are made out of a variety of materials, including, plastic and cardboard, but most are made out of metal.

Cookie tins are often decorated with festive designs or unique pictures. They are popular gifts during the holiday season. Cookie tins can also be used to store other food items, such as candy and nuts.

There are a variety of materials that cookie tins can be made from. The most popular material is metal, as it provides a sturdy and durable option. However, cookie tins can also be made from plastic, wood, or even glass. But the question is: which one of them is the best choice?

Plastic cookie tins are a good lightweight option, and they’re usually very affordable. However, they’re not as durable as metal tins and might not offer as much protection for your cookies. Besides, it may look cheap than other kinds of packages.

Wooden cookie tins can be very beautiful and elegant. However, they’re not even as durable as metal or plastic tins, and they can be more expensive. Actually, the wooden tins may be more suitable for containing other items, it is just not the proper choice for cookies.

Glass cookie tins can offer a clear view of your cookies, which can be convenient if you like to see what you’re getting. However, they’re very breakable and heavy.

Metal cookie tins are the most popular option, as they’re durable and offer a good level of protection for your cookies. They are not expensive compared to many other options. Whether metal cookie boxes are made of stainless steel or aluminum, they are very light. You can save as much as possible on shipping costs.

We need to figure out: who are the people who customize cookie tins? And why? The former question is just simple, they are the brand owner or manufacturer of cookies.

The latter question is more complicated, the reasons are as follows:

Compared to carton packaging and bags, custom cookie tins are significantly tougher and have better resistance to compression. Cookies are very fragile food and always need to be protected, whether in transit or on the supermarket shelf.

There are always bumps during the transportation of cookies, which may cause them to crumble. In carriages or warehouses, cookies are often stored in piles of layers. Custom cookie tins made of metal can be stacked higher and save more on storage costs.

The delicacy of custom cookie tins is more than a box or bag. Consumers are more likely to notice cookies packaged in cookie tins. Market research has shown that cookie tins are more popular because this type of packaging creates a good impression on consumers. In contrast, bagged cookies give an impression of cheapness.

When you have finished eating the food in the cookie tins, you can wash and dry the tin and use it as a storage box, which is both environmentally friendly and economical.

Custom cookie tins can also be used for decoration. They can be used to display cookies at a party or event. They can also be used to make a unique and personal gift.

Round cookie tins are common in canned cookies. If you’re looking for a unique and attractive way to package your cookies, look no further than round cookie tins. These tins are available in a variety of sizes and can be customized with your own designs, logos, and photos. They’re perfect for gift-giving, party favors, or simply storing your delicious homemade cookies.

Cookie tins with transparent windows are very popular with consumers. Today’s snack market is diverse, If your cookies have a novel shape or just look delicious, then cookie tins with window tops will be a good fit for your product.

Similar to the round cookie tins, the square cookie tins are also popular. Not only is it aesthetically pleasing, but it is also more logistically compatible with shipping conditions: square packaging makes better use of space than round. Moreover, square cookie tins are less prone to deformation in the event of accidental crushing.

Decorative cookie tins are one of the most beautiful and stylish packagings. You don’t need to care whether they use the space wisely or not. Because cost is not a priority for this type of cookie tins. Cookies packaged in decorative cookie tins tend to be more expensive and are suitable for holiday gifts or souvenirs. Although the cost is slightly higher and there are not too many cookies in each small tin, this has not stopped the popularity of decorative cookie tins in any way.

The answer is yes, cookie tins can be recycled! First, the tin is clean and free of any food residue, they are easy to recycle. Second, All of the recycling centers accept metal cookie tins. Some centers only accept aluminum, but most of them are ok with steel and aluminum.

You can either place them in your recycling bin at home or drop them off at a recycling center. Cookie tins are a great way to enjoy your favorite cookies while also being eco-friendly!

Through recycling, 40-75% of Europe’s metal needs could be met by 2025. With the introduction of strict EU regulations limiting carbon emissions, recycling of metals has become the trend of the future.

In fact, most cookie, chocolate and puffed food manufacturers choose custom cookie tins, for example, David’s, Lambertz, Matilde Vicenzi, Oreo, European Chocolate, Royal Dansk, and others.

Yes, they are absolutely safe. cookie tins are made of food-grade materials, both metal and plastic are required to meet the food safety standards like FDA or ROHS tests. Many brands seal cookies in bags before placing them in cookie tins to increase shelf life and increase food safety.

However, at no time do we recommend that you heat cookie tins directly, as this may lead to unnecessary and accidental injury.

If you want to buy a few cookie tins as gift wrap or to store your snacks, you can go to a nearby supermarket or convenience store and buy them directly.

If you are a manufacturer of snacks or cookies and need to purchase cookie tins in large quantities, then contact us and we will provide you with a professional solution to meet your sales goals.

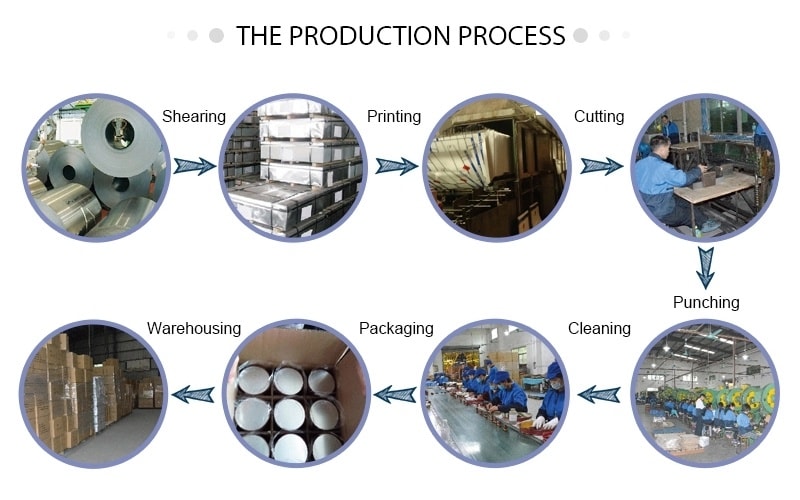

Before entering the production process of cookie tins, we first cut the iron or aluminum sheets (usually delivered in rolls) initially into small sheets one after another. The raw material of cookie tins is purchased directly from our origin, which is cheaper and of better quality. This is the first and most important step to ensuring the quality and safety of your products.

Our Fuji 4-color UV printing machine has the industry’s leading printing technology and can print all the patterns at once, which greatly avoids the color difference caused by repeated printing.

After printing the cookie tins, we also color the metal plate to avoid fading or paint loss and to prevent rusting.

Unlike the first step of shearing, this step is done in preparation for the subsequent punching. We will further cut the sheet metal into a specific shape, of course, this is calculated in advance.

In this process, there is a possibility of inferior products with raw edges or inaccurate dimensions. At Fine Tins, these situations are almost impossible because we use the most advanced fully automatic cutting machines.

Stamping Forming is the most important and essential step in the whole production process of cookie tins. If something goes wrong in this step, all the work will be lost. Failure in stamping can result in thousands of defective products on a production line, which can have a significant impact on delivery times.

Therefore, customers must choose the cookie tins manufacturer carefully and make sure to inspect the production plant carefully when visiting the factory to avoid risks to the maximum extent.

In the process of producing cookie tins, it is inevitable that debris and bacteria will be left in the tins. Therefore, at the end of production, we will fully sterilize and clean the cookie tins to ensure that each cookie tin handed to you is clean and hygienic.

During a long sea journey (this usually takes 20 to 40 days), problems can arise if the packaging is inadequate, such as:

To avoid these problems, we pack each cookie tin in OPP bags and use airbags to avoid collisions during shipping.

If you are temporarily unable to receive your shipment due to force majeure, that’s okay, we have a huge warehouse to store your cookie tins and will be able to send out your shipment quickly when the time comes.

Don’t worry about humidity, our warehouse is well protected from rain and moisture, and is maintained and inspected by dedicated personnel.

Customizing cookie tins can be very complex and there are many details that need attention. If you are customizing cookie tins for the first time, you are sure to make some mistakes: misjudging the size, unreasonable or overly complex shapes, picking the wrong pattern design, etc.

The size of the cookie tins can be customized according to your requirements, depending on how many cookies you want to put inside a cookie tin and the size of the cookies. The same series of cookies may be packaged in different capacities, and that’s okay, you can customize multiple sizes of cookie tins at the same time to meet your sales needs.

Generally speaking, cookie tins are mainly round and square in shape. Of course, many holiday specials or cookies developed for children will require a more varied shape. As a professional cookie tins manufacturer, we can customize cookie tins in various shapes according to your requirements.

What you may not know is that not all cookie tin manufacturers have a stable and quality supply chain of raw materials. The selection and supply of raw materials, has always been one of our strengths.

The pattern design can be considered one of the factors that directly affect sales, as the first thing consumers notice is often the packaging of the cookies. The pattern design needs to meet the aesthetic standards of your target customers. In addition, we can also customize special packaging for holidays or seasons, such as Christmas, Easter and Children’s Day.

The common printing methods of cookie tins are screen printing, CMYK printing and laser printing. Our printing quality is guaranteed by using the most advanced fully automatic printing machines and non-toxic pigments.

China is the world’s largest producer of metals, and we have the most stable supply and the cheapest prices. A stable supply chain and favorable prices can ensure our cost is low enough. This means that we can offer relatively low quotations.

Although you can find cheaper labor in Southeast Asian countries, we all know that their production skills and craftsmanship are nowhere near the level of China.

China is one of the most populous countries in the world, and we have an ample workforce and a large enough area to place larger-scale assembly lines. This means that our labor costs are actually lower than those of Southeast Asian countries.

Usually, a small portion of the cost of consumables is included in the price of cookie tins. For example, printing, energy supply for production machines, shipping costs, etc. If you buy in large enough quantities, these costs are not even worth mentioning. This is one of the advantages of cookie tins manufacturers: the more you buy, the cheaper the unit price will be.

Fine tins’ extensive experience can help you solve every problem in the procurement and production process. If you are looking for opportunities in cookie tins wholesale, leave the difficulties to us, and what we will give you will only be the perfect cookie tins.

Kerry Lu

I'm Kerry, the CEO of Finetins. I run a company with over 60 people, we produce, sell and export tin packaging. I spent over 20 years in tins packaging industry. We can provide you one-stop service of tin packaging purchase, including design, produce, export tin products to your place. If any questions, freely to reach me,I'll try my best to give you advice and solution.

Get in touch with our tin packaging specialist now.

CONTACT

Copyright © 2012 - 2024 Finetins